Sustainable Plastics

Packaging for the Future

Many people firmly believe that the words “sustainable” and “plastics” are mutually exclusive. The The miseducation and media propaganda with no scientific support on what biodegradability and sustainability mean have led the average consumer to think of plastic as one of the biggest environmental problems.

Furthermore, as a society, we have become increasingly reliant on plastic packaging to help keep our food safe and fresh, our medical tools sterilized, and give our pet food a longer shelf-life. From the year 1964 to 2014, plastic consumption has increased 20 times!

Is there a solution that will allow us to continue to rely on our plastic packaging while also protecting our environment?

The short answer: yes.

Sustainable plastics are here, and they are our future.

Why Flexible Packaging?

Because of plastics, we have access to fresh food that not only has a longer shelf-life but can also travel long distances.

It isn’t feasible for us to stop using plastic entirely when you take in the consideration of the complete life cycle. This is especially true when you consider the environmental impact of transporting plastic alternatives such as glass jars. Did you know that to transport equal amounts of product, it would take 26 truckloads for glass packaging as opposed to just one truckload for the same volume of flexible packaging?

That’s where BioFlex™ flexible packaging comes in. BioFlex™ was designed specifically for discard, meaning that it will increase landfill gas production 23 times faster within the managed lifetime of a modern landfill.*

Flexible packaging is not only a sustainable end-of-life solution, it also uses fewer resources to create, transport, and dispose.

At the end of its life, your packaging will be given a second life as harvestable, clean, green energy. This energy can be used to fuel anything from electric cars to the power grid that provides energy to your home!

What Makes BioFlex™ Flexible Packaging Sustainable?

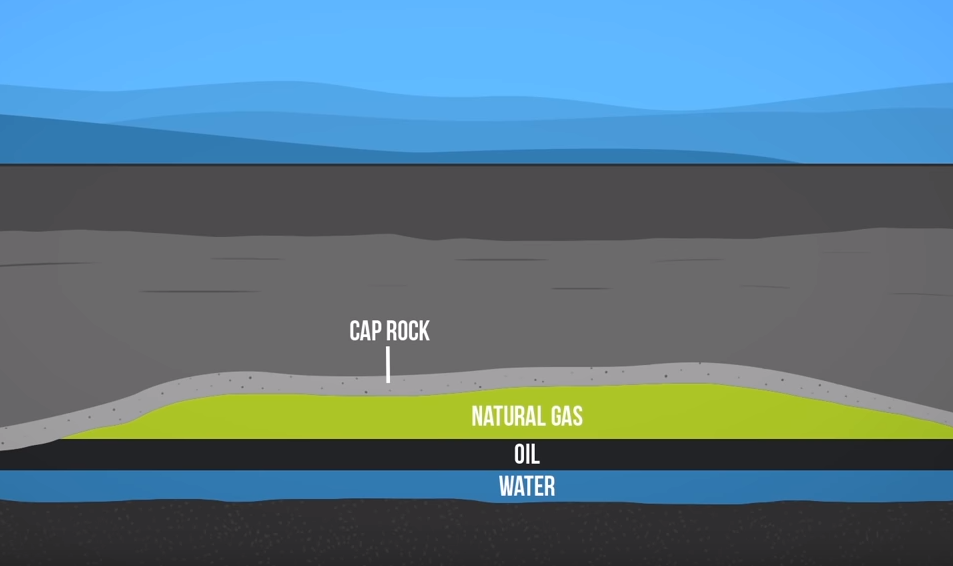

BioFlex™ is engineered to increase biogases in modern capped landfills. This means that BioFlex™ will accelerate the natural microbial process creating biogas in the landfill that can be converted into natural gas.

BioFlex™ maintains package integrity and will not change the barriers or physical properties of the package. Food manufacturers and processors do not require any special equipment or need to make any adjustments to the packaging process. Unlike other biodegradable products, BioFlex™ will not break down from oxygen or UV rays. This product does not require any special handling, so consumers do not have to change their behavior or adjust the way they discard packaging.

As is, most plastics end up in the landfill and can take up to 1,000 years to be turned into biogases. Some bioplastics made from corn or sugar are labelled as “compostable,” however, there are still many conditions which must be considered before the plastic can properly degrade. You may need to take bioplastic packaging to an industrial composting facility. In addition, there is a lot of consumer confusion around what can and cannot be recycled, composted or sent to the landfill.

With BioFlex™, there is no confusing process to remember or educate consumers on – you simply discard your packaging in the trash and let the science behind our flexible packaging do the rest.

What Are the Features of Sustainable Plastics like BioFlex™

Most landfills are equipped to capture the Land Fill Gas (LFG) produced by the BioFlex™ package and converted into renewable and sustainable energy. In the U.S. there are currently 619 modern landfill projects, and in Canada, there are 64 projects.

BioFlex™ is the perfect solution for utilizing today’s readily available energy conversion infrastructures in almost all the metropolitan cities in North America.

The convenient and effortless disposal method makes BioFlex™ the most responsible and sustainable choice for packaging any products in plastic.

Indeed, trying to find a way to recycle modern plastics has become increasingly difficult as companies find new and innovative ways to preserve food and increase shelf-life. While it is possible to recycle these materials, it is often a labourious and costly process that itself can cause high rates of greenhouse gas emissions.

BioFlex™ is a practical sustainable solution for today. BioFlex™ packaging can be recycled in some cases and also helps to create energy that can be used to power entire neighbourhoods and electric cars!

What Can I do as a Consumer?

At BioFlex™ we believe that education is the answer. As a consumer, your purchasing choices can make a difference. When you buy a product, you essentially support the brand and their corporate values.

Knowing exactly which types of flexible packaging you can and cannot recycle, is the first step in our journey to more sustainable plastics.

Check out our Consumer Solutions page for more information and tips on how you can help join the Packaging for Good movement.

A Practical, Sustainable Solution

The journey to BioFlex has taken over a decade and we are continuously innovating so that we can provide sustainable solutions for you and our planet. We like to think our journey has been a labour of love and a commitment to bettering our planet for current and future generations.

Whether you are a consumer who wants to be more educated on living a sustainable life or a manufacturer looking to improve their own practices, BioFlex™ Flexible Packaging is a truly sustainable solution.

*BioFlex™ has been shown to produce biogases 22 times faster than conventional plastic in the ideal conditions of an anerobic digestor landfill over the course of 2.13 years, using the ASTM D5511-12 test. When disposed of in a landfill with modern biogas capture technologies, this energy can be harnessed as a source of renewable energy. Such a facility may not exist in your area