Packaging for the Future

Why is Sustainable Packaging the right choice?

Packaging is single-use, and typically ends its life in a landfill.

Packaging That Supplies

Energy to Our Power Grid

Your packaging can increase the production of clean, sustainable energy using today’s modern landfill infrastructure*.

Harness the Power of Sustainable Packaging with BioFlex™!

BioFlex™ products are different than conventional plastic packaging that can’t be efficiently recycled, composted, or disposed of in landfills without being costly, time-consuming or environmentally damaging. Bioflex™ is a sustainable technology that increases the natural microbial activity in modern landfills, and contributes 19 times more energy than that of regular plastic.

This is different than current plastics that do not break down and can last for hundreds of years. No one will be confused with what to do with their post-consumer plastic packaging anymore. It looks and works just like most plastic containers, except it won’t sit in the landfill for generations.

Reduce your environmental impact and use Bioflex™ packaging. Contact one of our Sustainability Packaging Experts today.

* BioFlex™ has been shown to produce biogases 22 times faster than conventional plastic in the ideal conditions of an anaerobic digestor landfill over the course of 2.13 years, using the ASTM D5511-12 test. When disposed of in a landfill with modern biogas capture technologies, this energy can be harnessed as a source of renewable energy. Such a facility may not exist in your area.

You'll Love What We've Done with Plastics

How to Get Rid of Your Plastic Packaging Without Hurting the Environment.

*BioFlex™ has been shown to produce biogases 22 times faster than conventional plastic in the ideal conditions of an anaerobic digestor landfill over the course of 2.13 years, using the ASTM D5511-12 test. When disposed of in a landfill with modern biogas capture technologies, this energy can be harnessed as a source of renewable energy. Such a facility may not exist in your area. Such a facility may not exist in your area.

BioFlex™ is a solution for today, that recovers energy from our post-consumer plastic waste. *

Did you know, modern landfills are converting waste to energy?

Imagine if we could recover energy from your post-consumer plastic waste with infrastructure that already exists in many areas. BioFlex™ is a solution for today that can recover energy from our post-consumer plastic waste*.

Why This Matters

With 7.2 billion people on this planet, we use an astonishing amount of plastic. In 2014, the annual global production of plastic was 311 million tons. This has increased over 20x since 1964. Projections estimate global plastic production will continue to surge, doubling over the next 20 years. Packaging is the largest market segment in plastics and currently accounts for around 26% of the total volume of plastic used.

This is BioFlex™

Introducing a revolution in plastic design.

A Packaging Revolution

BioFlex™ is a packaging solution that is designed for disposal in landfills. When disposed of in a modern gas capture landfill, BioFlex™ can create clean energy *. BioFlex™ is an easy-to-use product that requires no change in consumer habits.

Designed for Landfill

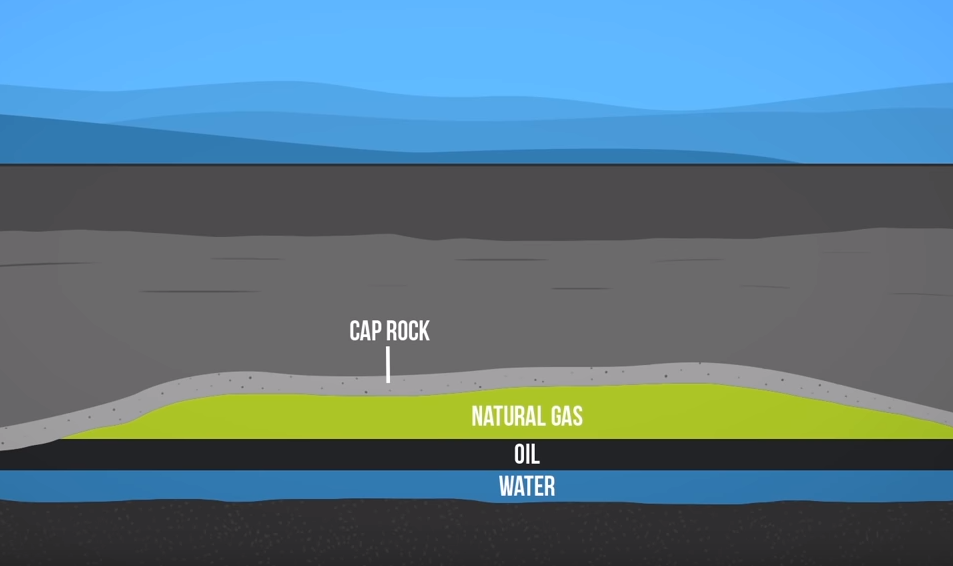

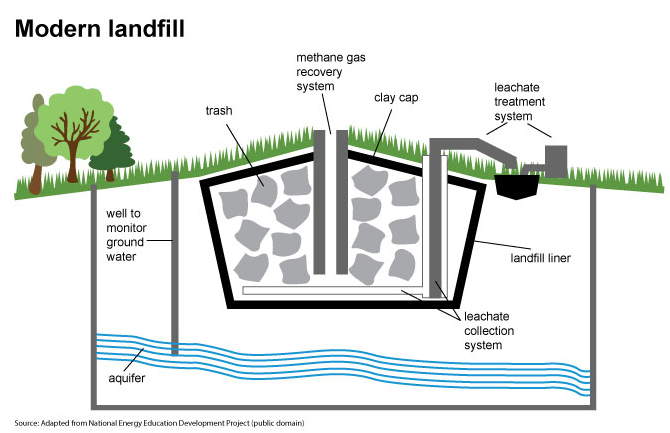

Microbes commonly present in managed landfills use BioFlex™ packaging to create biogas, which is a potential source of renewable energy*. Approximately 20% of U.S. landfills capture biogas today, focused in larger municipal areas. To see if such a facility exists in your community, click here.

Creates Energy

Landfill gas collection diverts greenhouse gas emissions by capturing naturally occurring biogas from decomposing matter in a landfill. Biogas can then be used to create power, offsetting fossil fuel usage. Approximately 20% of U.S. landfills capture biogas today, focused in larger municipal areas. To see if such a facility exists in your community, click here

BioFlex™ flexible packaging is designed to be discarded in a landfill at the end of its life. The material is designed to create biogas that can leverage gas collection systems to help create energy*. Many landfills are currently using biogas to create energy which powers homes, electric cars, and more.

Conventional flexible packaging is extremely resource-friendly compared to other materials; however it cannot be efficiently recycled as it is often composed of multiple layers of different types of plastic. BioFlex™ is a solution that allows brand owners and consumers to benefit from multi-layer flexible packaging with super properties while also addressing responsible packaging end-of-life considerations.

Microbes commonly present in managed landfills use BioFlex™ flexible packaging to produce biogas which can be captured and used to power anything from your home to an electric vehicle*.

Many modern landfills are designed to capture landfill gasses. Conventional packaging (which can take hundreds of years to break down) will not contribute to biogas production. BioFlex™ increases Biogas production in modern landfill environments*.

Landfill gas collection is a sustainable technology in which methane gas (commonly referred to as biogas) produced from decomposing matter in landfills is used to create energy. This harnessed energy can be used in many ways, from heating your home to powering your electric vehicle, offsetting fossil fuel usage.

So, what makes BioFlex™ different than conventional plastic packaging? Conventional plastics can take hundreds of years to break down in a landfill, so they do not contribute to biogas production. While we can’t say exactly how fast, because each landfill environment is different, BioFlex™ flexible packaging is designed to increase Biogas production, contributing to energy production from landfill gas*

*BioFlex™ has been shown to increase Biogas production up to 46.3% compared to traditional plastic packaging in the ideal conditions of an anerobic digestor landfill over the course of 695 days, using the ASTM D5511-12 test. When disposed of in a landfill with modern biogas capture technologies, this energy can be harnessed as a source of renewable energy. Such a facility may not exist in your area.

A SUSTAINABLE APPROACH TO PLASTIC WASTE

Compostable, Recyclable, Landfill– what do these really mean and, more importantly, what is their true impact on our environment?

BioFlex™ is a viable end of life solution for plastic waste

COMPOSTABLE PACKAGING

COMPOSTABLE PACKAGING RECYCLABLE PACKAGING

RECYCLABLE PACKAGING LANDFILL

LANDFILLHow BioFlex™ Reduces Your Carbon Footprint

BioFlex™ is sustainable packaging, designed for modern landfills.

You may be surprised to learn that plastic is made of organic material – just like all food, plants, and animals. BioFlex™ is designed to use the potential energy in plastic molecules, rather than locking it in a landfill. BioFlex™ creates biogas from packaging that can be captured by landfills and used for energy to offset fossil fuels. Every 1lb. of discarded BioFlex™ packaging could power a small electric vehicle for 13 kms.

Unlike other solutions, BioFlex™ utilizes existing infrastructure and does not require consumers to change their habits. This makes it very likely that a BioFlex™ package will end up in a landfill and fulfill its intended end-of-life – putting energy back into the grid!

As a brand owner or a consumer, it is always important to verify sustainable solutions and claims. BioFlex™ has been verified through standardized third-party testing including ASTM D5511, D5526, and BMP (Bio-Methane Potential) to confirm that BioFlex™ increases biogas production and does not merely break down into small pieces, which can be harmful to the environment.

COMPOSTABLE PACKAGING

COMPOSTABLE PACKAGINGCompostable plastics are typically made from polymers derived from corn or sugar cane, such as PLA and PHA. Compostable plastics are designed to degrade in aerobic (oxygen-rich) environments, only under specific conditions. For this reason, compostable plastics will generally not degrade in your backyard compost bin, they will only degrade in certain industrial compost facilities.

Challenges:

- Compostable plastics on the market today are not all appropriate for flexible packaging in which oxygen and moisture barriers are required to keep food fresh.

- It is difficult to differentiate between compostable and conventional plastic, so some municipalities will not accept compostable plastics (including products that are certified compostable). At compost facilities, all plastics, including compostables, are typically sorted out and sent to the landfill. Visit your local municipality’s website to find out if compostable plastics are accepted in your area.

- Compostable plastics that end up in a landfill are not designed to biodegrade in landfill environments and will exist for hundreds of years, like conventional plastic.

- Compostable plastics are generally not recycled.

RECYCLABLE PACKAGING

RECYCLABLE PACKAGINGRecycling can be a great end of life solution for single-use plastics as we are able to divert waste from the landfill and create new products, which offsets demand for new raw materials.

The recycling industry is making great efforts to educate consumers on what can be recycled. It basically comes down to one principle: plastics are recyclable when they are made from a single material. This includes soda bottles (made from PET), grocery bags (made from LDPE), and laundry detergent bottles (HDPE).

Many municipalities do not accept items like grocery bags because the value of the recycled material does not offset the cost to collect and process it. Visit your local municipality’s website to find out what products can be recycled in your region.

Challenges:

- Most flexible packaging is non-recyclable including items such as potato chip bags, meat packaging, and coffee pouches. This is because these packages are typically made of multiple layers of different types of plastics. It is currently extremely energy intensive to separate these materials, and therefore the packaging is landfilled.

- Easy to recycle single material packaging is not always the most sustainable choice because it may compromise packaging performance leading to food spoilage. This has a significant negative environmental impact as the production of food is extremely resource intensive.

- Only 14% of plastic packaging is collected for recycling. When additional losses from sorting and reprocessing are factored in, only 5% of material value is retained for a subsequent use.

- When plastics are recycled, the material properties are degraded. Plastics can only be recycled a few times before they have no value and are ultimately landfilled. Furthermore, most plastic is “down-cycled”, which means that the recycled material is used in lower demand applications.

LANDFILL

LANDFILLIn North America, most plastic packaging ends up in a landfill. This is both an opportunity and a problem. Imagine if this plastic could create a very meaningful amount of energy. Conventional, compostable, and recyclable plastics can take hundreds of years to break down, consuming valuable landfill space, and locking the energy potential of the plastic away.

However, today’s landfills are not the garbage heaps of yesterday. Thanks to increasingly stringent regulation, modern landfills are engineering marvels, designed to protect the soil, water, and air around them.

You may be surprised to know that modern landfills can actually be a source of renewable energy. As trash decomposes, it releases methane (commonly referred to as biogas). Methane is a powerful greenhouse gas, so many modern landfills are capped to capture this gas. And, where the facilities are available that captured gas can be used as a fuel for energy generation. The use of biogas can offset the use of fossil fuels to generate energy.

The U.S. EPA endorses landfill gas as a renewable energy resource, along with wind, solar, and geothermal energy. When we refer to a “modern landfill”, we are referencing landfills that are capped to capture biogas and use it to generate energy. In 2017, this included more than 370 landfills in the U.S. alone, which generate approximately 11.5 billion kWh of electricity annually.

What if our plastic waste could contribute to this renewable energy source? BioFlex™ films are designed to increase biogas production in modern gas-capture landfills*.

*BioFlex™ has been shown to produce biogases 22 times faster than conventional plastic in the ideal conditions of an anaerobic digestor landfill over the course of 2.13 years, using the ASTM D5511-12 test. When disposed of in a landfill with modern biogas capture technologies, this energy can be harnessed as a source of renewable energy. Such a facility may not exist in your area. Such a facility may not exist in your area.

How Your BioFlex™ Waste Can Contribute to Landfill Gas Energy.

You read that right. A responsible solution for the environment is to throw your BioFlex™ plastic right in the garbage. Most people are shocked to find out that most of the post-consumer plastic waste ends up in the landfill anyway – even the stuff they recycle and compost! The energy harnessed by modern landfills with gas collection systems capture the biogas to be converted to natural gas. This renewable energy can be sent back to our power grid to heat our homes and power our electric vehicles.

ENERGY PRODUCTION FACTS

In 2015, Landfill Gas (LFG) energy projects produced enough energy to power 1.3 million homes in the US*

Modern landfills can generate biogas 24 hours a day, 7 days a week - unlike sun or wind that are dependant on other factors

LFG energy projects can capture 60 to 90% of the methane from decomposing garbage that would otherwise be emitted to the atmosphere

The number of LFG energy projects increased from 370 in 2017 to 619 in 2019 - a 67% increase in two years

Current operational LFG energy projects can produce up to 16 billion kilowatt hours of electricity, and 99 billion cubic feet of landfill gas to end users annually*

*BioFlex™ has been shown to produce biogases 22 times faster than conventional plastic in the ideal conditions of an anaerobic digestor landfill over the course of 2.13 years, using the ASTM D5511-12 test. When disposed of in a landfill with modern biogas capture technologies, this energy can be harnessed as a source of renewable energy. Such a facility may not exist in your area. Such a facility may not exist in your area.

Make a Difference!

Join our packaging revolution to receive news, education, and tips on living more sustainably.

Join the revolution today

Join our movement by turning today's packaging waste into tomorrow's clean energy.

Approximately 90% of plastics will end up in a landfill

%

Approximately 16 billion kWh of electricity is generated in the US annually from landfill gas

As of February 2019, there were 619 operational landfill gas energy projects in the US.

©BioFlex™ 2019. All rights reserved.